SPAIN

GERMANY

FRANCE

ITALY

DENMARK

GREECE

Participating partners

The Danish cMDF is composed of two partners: BetaFactory (the cMDF representative) and the Copenhagen Business School (a university).

Scope and purpose of the cMDF

The Danish cMDF aims to democratize ‘making’ by expanding the knowledge and expertise about the potential of local production through partnerships with different groups of stakeholders, including educational institutions (schools and universities), SMEs, and businesses. Among the activities of the cMDF, a mobile lab unit containing a set of machines has been created and equipped to provide a mobile production facility that can be deployed in various locations, linked to specific on-site production workshops and activities.

Expansion strategy

Besides keeping the current customers through improvements in the quality of service provided, workshops and courses serve as tools to reach new customers and expand the pool of workshop members. In addition to these actions, developing local projects with larger industry partners from the construction, design and development sectors is a way to create fruitful synergies and long-term partnerships towards new services focusing on sustainable local production.

Key services

The main services offered by the Danish cMDF are:

|

Prototype and production facility, local production on site, equipment and development of the mobile unit. Co-running of workshops, courses, disseminating local production capabilities through events and partnerships with potential partners from educational institutions (schools and universities), to SMEs and businesses. |

Identify and develop sustainable business models, based on BF’s vision and goals, aligned with market opportunities, Help BF to solidify and expand its business towards a healthy and sound development. |

Danish cMDF use cases

UC1: Co-creation in schools

Description of the use case

Currently, public schools across Denmark acquire existing ready-made solutions in the market when setting up their classrooms, libraries and other activity rooms. Besides the cost, many of the solutions are not optimised to the existing spaces. The UC focuses on inspiring teachers and students to think of digital fabrication as a low-entry method for making hands-on interior productions and urban space interventions. Also, the cMDF wants to enable schools lacking resources to offer these technologies to their students.

Objectives

The objectives of UC1 are to:

- Have at least 3 agreements in place with local Danish schools.

- Have run and deployed workshops in schools.

- Co-create and deliver developed units to schools.

- Engage schools in optimizing their spaces through learning and access to digital and physical manufacturing.

Methodology

Through co-creation workshops with local school groups and associations, the cMDF will define how to best engage primary and secondary Danish students to learn and experiment with digital fabrication and other sets of tools towards creating and developing furniture solutions to their school spaces.

Expected results

- Staff and the students have been successfully trained through a digital fabrication design, production and assembly process.

- Students have achieved new skills and understanding of STEM.

- Teachers have gained new knowledge about digital fabrication technologies.

- The school's ability to act on the new findings regarding makerspaces has increased.

UC2: Distributed design market

Description of the use case

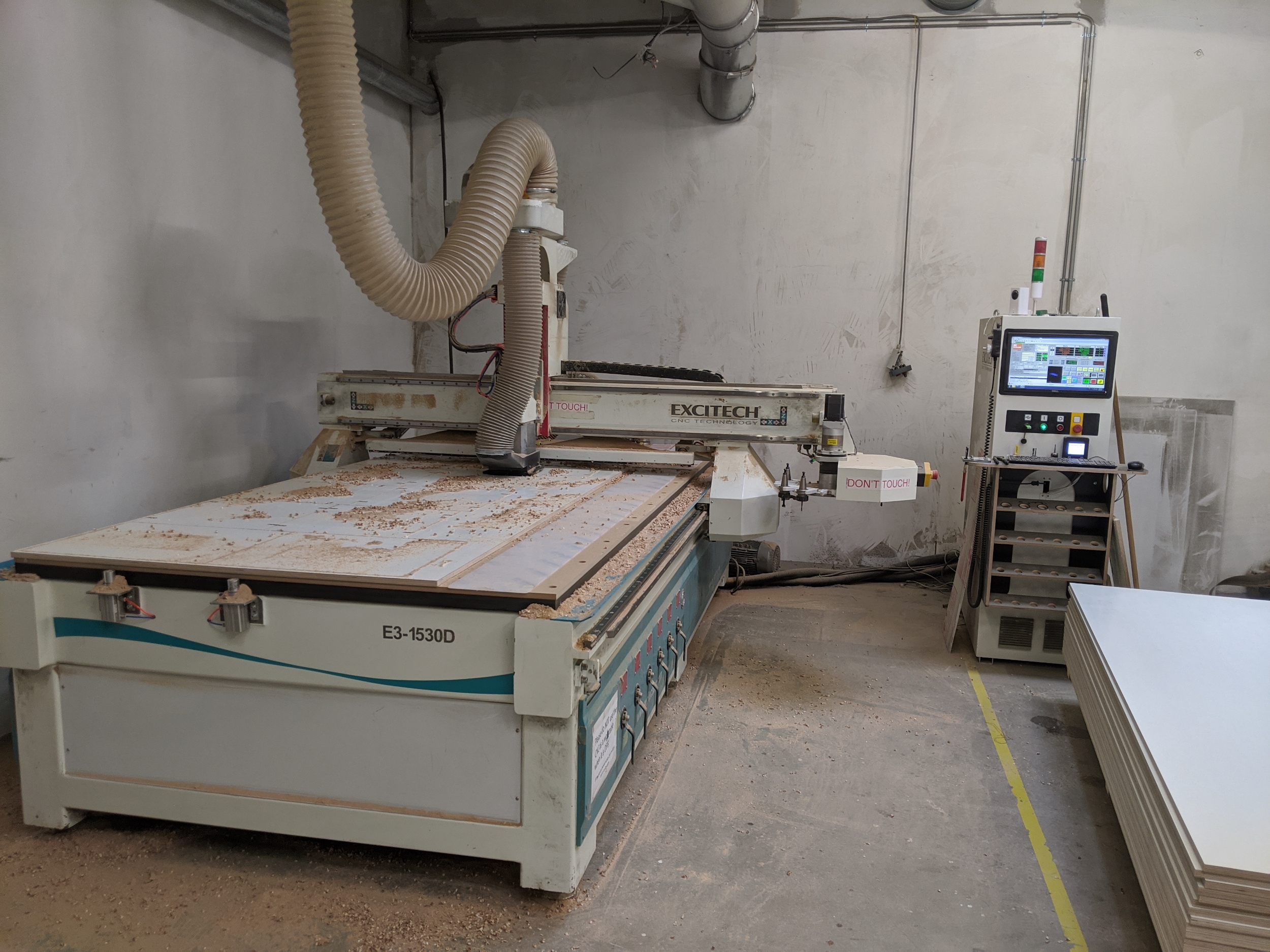

A client wants customised bespoke furniture for housing, exhibition or office purposes. Until now, this has been very high-end work done by architect studios and creative bureaux, while mostly subcontracting the build process to cabinet maker companies. By using a Mobile BetaFactory Unit, the project can be manufactured on site using CNC-technology. The client can be fully be immersed in the collaborative co-creation process as it happens, and ideas can be thought out and tested on site.

Objectives

The objectives of UC2 are to:

- Assess the ability for the BetaFactory mobile unit to be deployed and operational at most locations.

- Ensure a good iPRODUCE interface integration in the operation of the hardware.

- Ensure lower costs in customised furniture production.

Methodology

The client needs to get acquainted with the project and the platform, then possibly attend an online (or offline) workshop to learn more about the available opportunities within the iPRODUCE platform to use the mobile fabrication unity.

Before the customer goes to the mobile fabrication unit, he/she will have to have read an instruction with the expectations/requirements for a distributed design project.

When that has been done, the client needs to book a time slot for the design phase, and when finalising the design, schedule an appointment for the fabrication. When getting to the mobile fabrication unit, the customer and our staff will:

- Choose materials

- Make sure that the CAD drawings have correct measurements

- Check the auto generated in the iP CAM g-code viewer

- Execute the fabrication

Expected results

- Reduction of waste through on-site manufacturing capability of 20%.

- Improve local manufacturing awareness through the deployment of the mobile unit to reach at least 30 people.

- Increase the number of communities involved in collaborative manufacturing by at least 20.

- Improve the perceived ability of local manufacturing for local business stakeholders (by having 2 large manufacturers involved).

UC3: Temporary architecture

Description of the use case

Currently many venues, festivals, construction sites, among others, are building everything from scratch every time they start a new production. When the assignment is done they discard it and start from scratch again the year after or on the next assignment. By applying the cMDF's Mobile Production Unit in conjunction with the iPRODUCE platform to this use case, with assistance from the design and engineering team, the cMDF will create designs that will be parametric and more sustainable.

Objectives

The objectives of UC3 are to:

- Help SMEs, municipalities, and others save time on construction and get a unique customised project.

- Enable faster product to market.

- Ensure sustainable focused architecture.

Methodology

- Co-creation workshops with the stakeholders to identify current needs and co-create solutions.

- Hands-on learning with design thinking concepts and fabrication.

- Co-create a new space for a festival/event (eg. benches, seating, signage, visual installations, separations walls).

- Modular, adaptive and parametric designs.

- AR viewer - used for presentations on venue.

- Change the way temporary design is applied.

Expected results

- Developed 2 proof of concepts for working with AR within manufacturing.

Reduction of waste through on-site manufacturing capability). - Having 2 proofs of concept of waste as resource through parametric modularity.

- Apply co-creation and physical prototyping in architecture to at least 1 project.

- Increase number of architecture firms involved in collaborative manufacturing to reach at least 10.

- Improve the perceived ability of local manufacturing of 1:1 scale prototypes for local business stakeholders.